Do You Already Have A Lean Mindset?

Gerelateerde artikelen

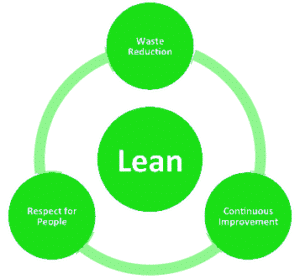

Mindset

AT Kearney published the Toyota case. Toyota has enforced a continuous attention for improvement of cost, quality, and service. This has resulted in becoming the largest automobile manufacturer. Many companies and organizations have adopted since then the lean mindset. At least they tried: They used tools like 5S, the shadow board, and the Kaizen workshop. Others have enforced a Six Sigma process to be used for everything. Unfortunately, many did not succeed. They found out the hard way that adopting tools is unequal to adopting a mindset. Thus the question is: What is needed to realize this lean mind-shift.

According to AT Kearney this takes the usage of 4 principles:

- Listen to the voice of all customers.

- Remove all related non-value-adding steps and procedures from the business process.

- Address bottlenecks by re-balancing resources.

- Establish an organizational structure to support continuous improvement.

Listen to the voice of all customers in this mindset

This is what I suggested in the two mentioned blogs about quality. Make sure that you know what your customers value.

Remove all related non-value-adding steps and procedures

I advocated this principle and the next one, address bottlenecks, in my blog regarding complexity.

AT Kearney sums up all types of wasted resources one can have:

- Mistakes;

- Ineffective processes;

- Production errors;

- Unnecessary movement of case files and other documents;

- Input and output buffers;

- Transportation;

- Waiting.

Address bottlenecks by re-balancing resources

Resources are scarce. Make use of them in the best way.

Establish an organizational structure to support continuous improvement

The continuous improvement process needs a clear owner. If the owner is inadequate, or cannot take the right and necessary enforceable decisions, the result will be only a partial optimization.

Discussieer mee op LinkedIn.

Mogelijk is dit een vertaling van Google Translate en kan fouten bevatten. Klik hier om mee te helpen met het verbeteren van vertalingen.

Laatste artikelen

- De IT-offerte: Waar moet je op letten bij Software en SaaS?

- De ICT-checklist voor het moderne kantoorgebouw

- De paradox van Cloud FinOps Governance: kostenbeheersing in de cloud

- De mens als AI agent: van meester naar slaaf

- Exploratief testen: Agile softwaretesting zonder testscripts

- DRY Principe: Fundament voor Schone Code en Onderhoudbare IT

- Citizen Developer Governance: Veilige Low-Code/No-Code voor medewerkers en compliance

- Uninterruptible Power Supply (UPS): Noodstroomvoorziening voor IT-Infrastructuur

- De Cloud Security Baseline: 10 kritieke auditpunten voor AWS, Azure en GCP

- Model Drift: de onvermijdelijke veroudering van AI-modellen